Trespa High-Pressure Laminates

Of necessity for facade durability and aesthetics’ sensibility came into being TRESPA, the mother company of high-pressure laminates. Founded in 1960, the cladding panels bring compelling aesthetics and nearly limitless design possibilities with various colours, rhythms, and depths to contemporary architectural buildings.

CATEGORIES

OUR PROJECTS

OUR EMAILERS

TRESPA, Netherland is the mother company of high-pressure laminates.

Founded in 1960, the cladding panels bring compelling aesthetics and nearly limitless design possibilities with various colours, surface finishes and thicknesses for contemporary architectural buildings. These panels are commonly used in applications such as facade cladding, balcony panels, wall panelling, and decorative elements in commercial and public buildings such as schools, hospitals, and offices as well as in high end residential bungalows due to their long lasting colour fastness properties.

High pressure laminates sheets offer following benefits :

- Durability

- Aesthetics

- Low maintenance

- Versatility

- Fire resistance

Specifications & Features :

Thicknesses Offered : 8, 10, 13 mm

Sizes Offered :

- 1220 mm * 2440 mm

- 1524 mm * 3048 mm

- 1829 mm * 3658 mm

- 2134 mm * 4268 mm

Fixing:

This is our USP as we offer a dry cladding which has no visible rivets on the front of the finished surface and no silicone behind. It is a completely concealed fixing with grooves of 8-10 mm between the sheets to let the air circulate around the panels which helps in preventing any warping of the panels in the long term.

EBC Treatment :

This treatment is a patented technology of Trespa to bring in lot of USPs in our high-pressure laminates. EBC(Electron Beam Curing) technology is a fast, non-thermal curing method using high-energy electrons at a controlled rate to cure special surfaces. This results in a closed smooth surface with excellent:

- Chemical resistance

- Long-lasting surface hygiene

- Impact resistance

- Scratch resistance

- Cleanability

Environmental-Specific Florida Testing :

We test all our panels using 3000 hrs in Florida testing method which simulates a 30 years of life in real application. Florida testing supposedly is the extreme most environmental condition combination of heat and humidity and this reflects the Indian weather conditions most appropriately. Competitors generally test and share the results based on European weather conditions as defined in EN 438-2:29 which doesn’t simulate the tough Indian weather conditions.

Though our product comes with a 10 year warranty for external usage in buildings, we have projects dating back to 30 years where nothing has happened to the color fastness of the material. So this will ensure that your bungalow will continue to look like as it was on day one even after 30 years.

FAQ

Trespa is a Dutch company that specializes in the development, production, and distribution of high-performance and high-quality architectural panels.

Trespa’s panels are widely used in the construction and architectural industries for applications such as building facades, cladding, interior wall panels, and more. Trespa’s products are known for their durability, versatility, and aesthetic appeal, making them a popular choice in architectural and design projects worldwide.

- What is Trespa and how is it made?

Trespa ® is a high-pressure compact panel (HPL), based on thermosetting resins, homogeneously reinforced with wood-based fibers and manufactured under high pressure and at high temperatures.

- Different Sizes and Thickness of High-Pressure Laminates?

HPL comes with a homogenous core and is available in four master sheet sizes with thicknesses of 6mm, 8mm, 10mm, and 13mm.

- What are Some Common High-Pressure Laminates?

Common types of high-pressure laminates include

- Where are High-Pressure Laminates Typically Used?

High-pressure laminates (HPL) are versatile and durable surfacing materials that find applications in a wide range of industries and settings. They are used primarily for decorative and functional purposes due to their resilience, ease of maintenance, and aesthetic versatility.

- Retail Showrooms

- Commercial Spaces

- Retail and Commercial Displays

- Restaurants and Cafes

- Healthcare Facilities

- Retail Stores

- Exterior Cladding

Features

Trespa High Pressure Laminates

Trespa High-Pressure Laminates (HPL) are renowned for their exceptional quality and versatility in architectural applications. These laminates are manufactured by Trespa International, a leading innovator in the field of high-performance exterior and interior paneling solutions. Here are some detailed features of Trespa Laminates:

Durability:

Trespa are engineered to withstand the harshest weather conditions and environmental factors. The high-pressure manufacturing process ensures a dense, sturdy composition that is resistant to impact, scratches, and UV radiation, making them ideal for both indoor and outdoor applications.

Weather Resistance:

Trespa HPLs excel in exterior applications due to their exceptional resistance to moisture, heat, and changing weather patterns. This feature makes them an excellent choice for cladding, façades, and other outdoor architectural elements, providing long-lasting performance and aesthetic appeal.

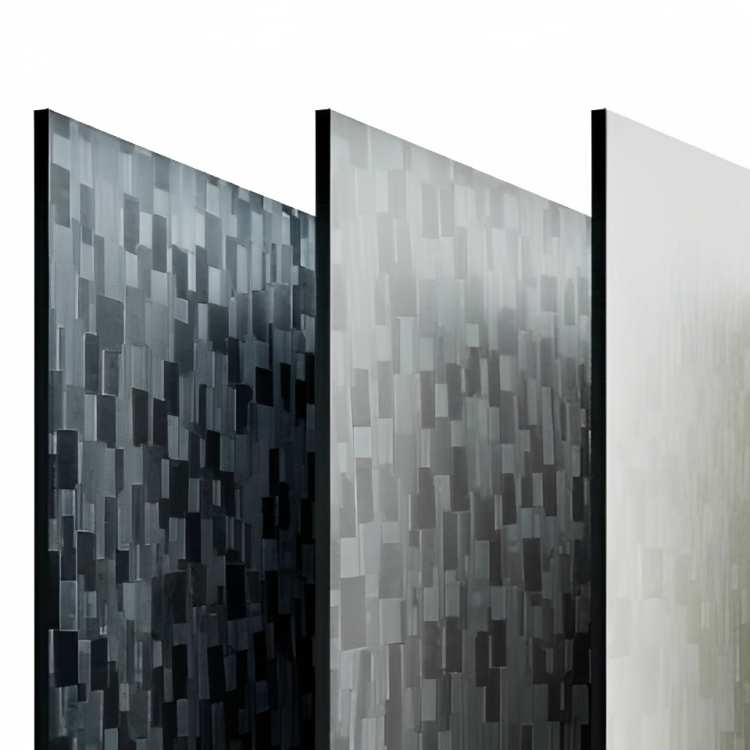

Design Versatility:

Vibrant Technik offers wide range of colors, patterns, and finishes, allowing architects and designers the freedom to create visually stunning and customized trespa’s surfaces. From vibrant colors to natural woodgrain textures, HPLs cater to diverse design preferences and can be seamlessly integrated into various architectural styles.

Easy Maintenance:

The non-porous surface of Trespa HPLs resists dirt, graffiti, and other contaminants, making them easy to clean and maintain. This feature is especially valuable for high-traffic areas or locations where cleanliness and hygiene are critical, such as educational institutions, healthcare facilities, or commercial spaces.

Fire Resistance:

HPLs meet stringent fire safety standards, providing an extra layer of protection for buildings. The materials are designed to be fire-retardant, adding a safety element to their application in both interior and exterior settings.